Welcome to Taizhou Ronghui Lighting Co., Ltd. official website!

Taizhou Ronghui Lighting Co., Ltd.

Contact: Zhang Zhang

Phone: 13606826568

Phone: 0576-88879998

Fax: 0576-88321332

Address: Building 3, No. 509, Tengyun Road, Haimen Street, Jiaojiang District, Taizhou City, Zhejiang Province

Website: tzronghui.com

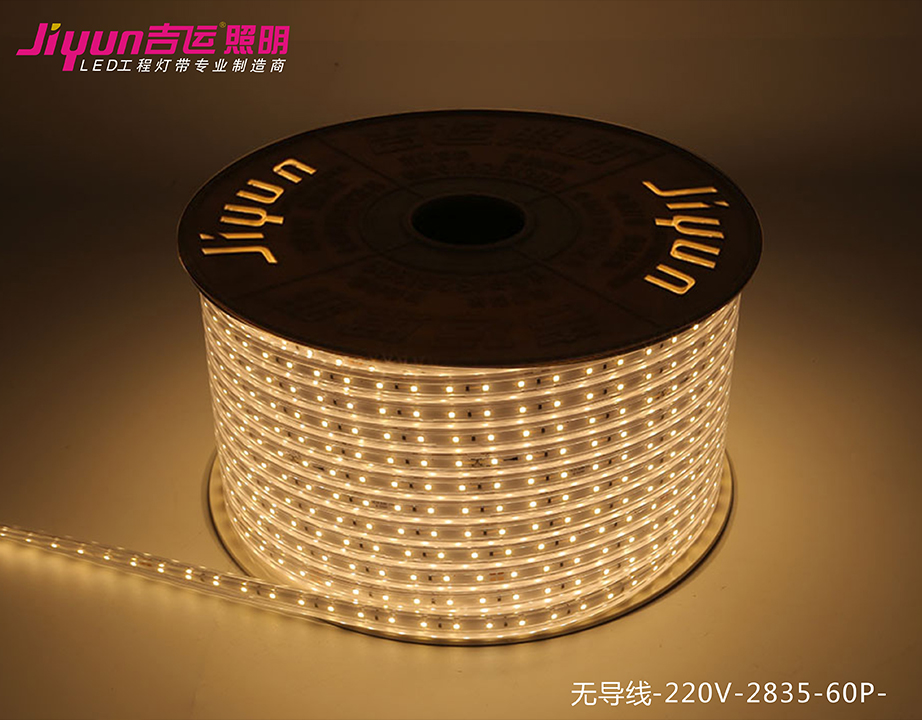

The light belt refers to the special processing technology of the LED lamp, which is welded to the copper wire or the ribbon flexible circuit board, and then connected to the power source, which is named after the shape of a light belt. Flexible lamp with the standard length of 50 meters, can be used in many places, such as a home or office interiors, stair, exhibition stand, thin light box advertising, solitaire lamp, bottom, veneer, the ambient lighting on the TV, etc., to rich and colorful, but also can be customized design flexible light band. The quality of products produced in the market is also uneven, and people without relevant knowledge and experience are easily tricked into buying inferior light belts. But experienced people still have a way to identify, and regular manufacturers produce LED lights and a shanzhai version of the flexible light belt that can be seen from the outside.

1. Look at the solder joints. The LED light belt produced by the manufacturer of normal LED light belt is produced by SMT patch and solder paste and reflow soldering process. Therefore, the solder of LED lamp is relatively smooth and the solder flux is not much. The welding spot is arc shaped from FPC solder to the LED electrode. However, the amount of solder solder in the shanzhai LED lamp is not uniform, which is more than one dot to cover the welding feet. At the same time, there will be different degrees of tin tip, which is a typical phenomenon of manual welding.

2. Look at FPC quality. The FPC is divided into two kinds of copper and calender copper. The copper foil applied to copper plate is convex, and it can be seen from the connection between the welding disc and the FPC. However, the copper is closely connected with the FPC, and can be bent at will without the loss of the welding disk. If the bending is too much, the welding disk will fall off, and too high temperature will cause the welding disk to fall off.

3. Look at the cleanliness of LED light belt surface. If the LED lamp is produced by SMT process, the surface cleanliness is very good, no impurities and stains can be seen. But if use hand welding production of LED lights LED, no matter how the surface cleaning, will remain with traces of the stain and cleaning, and will help in FPC surface residual flux and tin slag.

Look at the package. The normal LED light belt will be packed in anti-static coil, which will normally be 5 meters per roll or 10 meters, and then it will be sealed with antistatic and moisture-proof packing bag outside. But shanzhai will LED lamp belt because of cost savings, and use recycled coil plate, then no anti-static moisture-proof packaging bags, see coil plate can see appearance with clear label and tracks when cut.

Look at the labels. Regular LED lights with packaging bags and rolls will have a printed label, not a printed label. And the knockoff version of the label is printed, and the specifications and parameters are not uniform.

6. See the attachment. The normal LED light belt will be enclosed with the instructions and the lamp ribbon specification, and will be equipped with LED lamp belt connector or card holder. However, there are no such accessories in the shanzhai version of the LED light boxes, because some manufacturers can still save them.

Taizhou ronghui lighting is mainly engaged in Christmas lights, flexible lamp belt, flexible LED lamp belt, flexible lamp belt manufacturers, processing, sales management services.